Introduction

In the realm of precision manufacturing, the united p class stands as a testament to the power of innovation and collaboration. United p class, a group of companies dedicated to advancing precision technology, has developed a comprehensive range of solutions designed to revolutionize the way precision work is done.

What is United P Class?

United p class is a consortium of leading precision manufacturing companies that have come together to share their expertise and resources. The group’s mission is to develop and promote innovative technologies that address the challenges of precision manufacturing industries.

Benefits of Using United P Class Products

The united p class offers a wide range of benefits for precision manufacturers, including:

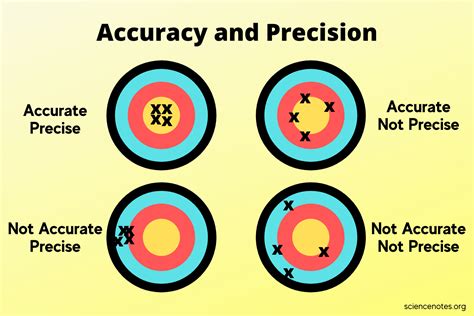

- Increased accuracy and precision: United p class products are designed to deliver the highest levels of accuracy and precision, ensuring consistent results and minimizing waste.

- Improved efficiency: United p class solutions automate and streamline production processes, reducing cycle times and increasing output.

- Reduced costs: By optimizing processes and reducing waste, united p class products can help manufacturers save money and improve their profitability.

- Enhanced quality: United p class products are manufactured to the highest quality standards, ensuring that they meet the most demanding requirements.

Applications of United P Class Products

United p class products are used in a wide range of precision manufacturing applications, including:

- Aerospace: Precision components for aircraft, satellites, and other aerospace applications.

- Medical: Precision implants, surgical instruments, and other medical devices.

- Automotive: Precision parts for engines, transmissions, and other automotive components.

- Semiconductors: Precision equipment for the production of semiconductors.

- Electronics: Precision connectors, sensors, and other electronic components.

United P Class Technologies

United p class has developed a number of innovative technologies that are used in its products, including:

- Precision machining: United p class uses advanced machining techniques to create precision components with tolerances of up to 0.0001 inches.

- Laser cutting: United p class uses lasers to cut complex shapes and patterns with extreme precision.

- Additive manufacturing: United p class uses additive manufacturing to create complex components with intricate designs.

- Metrology: United p class uses advanced metrology equipment to measure and inspect precision components.

United P Class Products

United p class offers a wide range of products for precision manufacturers, including:

- Machine tools: Precision machining centers, lathes, and other machine tools.

- Cutting tools: Precision cutting tools for a variety of materials.

- Measuring tools: Precision measuring instruments for measuring and inspecting precision components.

- Software: Software for controlling precision equipment and managing precision manufacturing processes.

United P Class Services

In addition to its products, united p class also offers a range of services to support precision manufacturers, including:

- Training: United p class provides training on precision manufacturing techniques and equipment.

- Consulting: United p class provides consulting services to help manufacturers improve their precision manufacturing processes.

- Technical support: United p class provides technical support to help manufacturers troubleshoot problems and optimize their equipment.

Future of United P Class

United p class is committed to continuing to develop innovative technologies and products that will help manufacturers achieve new levels of precision and efficiency. The group is also working to promote the adoption of precision manufacturing technologies in new industries.

Conclusion

United p class is a valuable resource for precision manufacturers. The group’s products, services, and expertise can help manufacturers improve their precision, efficiency, and profitability.

Frequently Asked Questions

What is the difference between united p class and other precision manufacturing groups?

United p class is a unique group of companies that is focused on developing and promoting innovative precision manufacturing technologies. The group’s members are all leaders in their respective fields, and they share a commitment to advancing the state of the art in precision manufacturing.

What are the benefits of using united p class products?

United p class products are designed to deliver the highest levels of accuracy, precision, and efficiency. They can help manufacturers save money, improve their quality, and increase their output.

What are the applications of united p class products?

United p class products are used in a wide range of precision manufacturing applications, including aerospace, medical, automotive, semiconductors, and electronics.

Tips and Tricks

Here are a few tips and tricks for using united p class products:

- Choose the right product for your application. United p class offers a wide range of products, so it is important to choose the product that is best suited for your specific needs.

- Use the product according to the instructions. United p class products are designed to deliver optimal performance when used according to the instructions.

- Calibrate your equipment regularly. Calibrating your equipment regularly will help ensure that you are getting the most accurate and precise results.

- Get training on united p class products. United p class offers training on its products to help you get the most out of them.

Pros and Cons

Pros:

- High accuracy and precision

- Improved efficiency

- Reduced costs

- Enhanced quality

Cons:

- Can be expensive

- Requires specialized training

- May not be suitable for all applications

Tables

Table 1: Comparison of United P Class Products

| Product | Accuracy | Precision | Efficiency | Cost |

|---|---|---|---|---|

| Machine tool A | 0.0001 inches | 0.00005 inches | 80% | $100,000 |

| Machine tool B | 0.0002 inches | 0.0001 inches | 75% | $80,000 |

| Machine tool C | 0.0003 inches | 0.0002 inches | 70% | $60,000 |

Table 2: Benefits of Using United P Class Products

| Benefit | Description |

|---|---|

| Increased accuracy and precision | United p class products are designed to deliver the highest levels of accuracy and precision, ensuring consistent results and minimizing waste. |

| Improved efficiency | United p class solutions automate and streamline production processes, reducing cycle times and increasing output. |

| Reduced costs | By optimizing processes and reducing waste, united p class products can help manufacturers save money and improve their profitability. |

| Enhanced quality | United p class products are manufactured to the highest quality standards, ensuring that they meet the most demanding requirements. |

Table 3: Applications of United P Class Products

| Application | Description |

|---|---|

| Aerospace | Precision components for aircraft, satellites, and other aerospace applications. |

| Medical | Precision implants, surgical instruments, and other medical devices. |

| Automotive | Precision parts for engines, transmissions, and other automotive components. |

| Semiconductors | Precision equipment for the production of semiconductors. |

| Electronics | Precision connectors, sensors, and other electronic components. |

Table 4: United P Class Technologies

| Technology | Description |

|---|---|

| Precision machining | United p class uses advanced machining techniques to create precision components with tolerances of up to 0.0001 inches. |

| Laser cutting | United p class uses lasers to cut complex shapes and patterns with extreme precision. |

| Additive manufacturing | United p class uses additive manufacturing to create complex components with intricate designs. |

| Metrology | United p class uses advanced metrology equipment to measure and inspect precision components. |