Introduction

Systems engineering and industrial engineering are disciplines that have often been intertwined yet distinctly different in their approaches and applications. Both fields contribute to the design, optimization, and management of complex systems, but they do so with varying perspectives and methodologies. In this article, we will explore the intricacies of each discipline, highlighting their unique contributions and charting the subtle differences that set them apart.

Systems Engineering: A Holistic Perspective

Systems engineering is an interdisciplinary field that focuses on the development, integration, and management of complex systems. It encompasses a wide range of activities, from concept exploration and requirements definition to system design, implementation, and testing. Systems engineers work across multiple disciplines, collaborating with experts in engineering, science, and business to ensure that the system meets its intended purpose, cost, and time constraints.

According to the International Council on Systems Engineering (INCOSE), systems engineering is “an interdisciplinary approach and means to enable the realization of successful systems. It focuses on defining customer needs and required functionality early in the development cycle, documenting requirements, then proceeding with design synthesis and system validation while considering the complete problem.”

Systems engineering is particularly valuable in the development of large-scale, complex systems, such as aircraft, satellites, and power plants. It provides a framework for managing the complexity of these systems and ensures that all components work together harmoniously to achieve the desired outcomes.

Industrial Engineering: A Focus on Efficiency

Industrial engineering, on the other hand, is a discipline that focuses on the optimization of processes, systems, and organizations. Industrial engineers work to improve efficiency, reduce costs, and enhance quality across a wide range of industries, including manufacturing, healthcare, and logistics. They use a variety of tools and techniques, such as data analysis, simulation, and ergonomics, to identify and eliminate bottlenecks, optimize workflows, and improve productivity.

According to the Institute of Industrial Engineers (IIE), industrial engineering is “the branch of engineering that deals with the optimization of complex processes and systems. It focuses on improving productivity and efficiency in a variety of industries, including manufacturing, healthcare, and logistics.”

Industrial engineering is essential in the design and management of production systems, supply chains, and service operations. It provides a framework for analyzing and improving the performance of these systems, ensuring that they operate at peak efficiency and deliver maximum value.

Key Differences: A Comparative Analysis

While systems engineering and industrial engineering share some commonalities, they exhibit distinct differences in their approaches, methodologies, and applications. The following table summarizes some of the key differences between the two disciplines:

| Feature | Systems Engineering | Industrial Engineering |

|---|---|---|

| Focus | Development and management of complex systems | Optimization of processes, systems, and organizations |

| Perspective | Holistic, systems-level | Process-oriented, focused on efficiency |

| Scope | Complex, multidisciplinary projects | Production systems, supply chains, service operations |

| Methodologies | Requirements engineering, systems analysis, system design | Data analysis, simulation, ergonomics |

| Tools | Modeling and simulation software, requirements management tools | Productivity improvement tools, lean manufacturing techniques |

| Applications | Aircraft, satellites, power plants | Manufacturing, healthcare, logistics |

Convergence and Collaboration

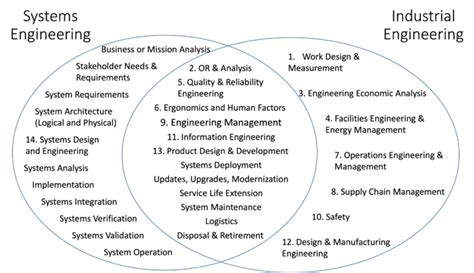

Despite their differences, systems engineering and industrial engineering often converge in the development and management of complex systems. Systems engineers bring a holistic perspective to the design process, ensuring that the system meets its intended purpose and performs reliably. Industrial engineers, on the other hand, contribute their expertise in optimizing system performance, ensuring that it operates efficiently and cost-effectively.

Collaboration between systems engineers and industrial engineers is critical to the success of many complex systems projects. By combining their unique perspectives and methodologies, these professionals can create systems that are both robust and efficient, delivering maximum value to customers and stakeholders.

Applications and Examples

Systems engineering and industrial engineering have a wide range of applications across various industries. Some notable examples include:

Systems Engineering:

- Design and development of aircraft and spacecraft

- Development of medical devices and healthcare systems

- Design and construction of power plants and infrastructure

Industrial Engineering:

- Optimization of manufacturing processes in automotive and aerospace industries

- Design and management of supply chains for retail and distribution

- Improvement of healthcare delivery systems and patient flow

Common Mistakes to Avoid

Both systems engineers and industrial engineers can encounter common pitfalls in their work. Some common mistakes to avoid include:

-

Systems Engineering:

- Failing to adequately define customer needs and requirements

- Focusing too much on technical details and neglecting the human factors

- Failing to consider the system’s life cycle costs

-

Industrial Engineering:

- Focusing solely on short-term gains and neglecting long-term sustainability

- Overreliance on technology without considering the human element

- Failing to involve stakeholders in the optimization process

Tips and Tricks for Success

To achieve success in either systems engineering or industrial engineering, it is important to follow proven best practices and techniques. Here are a few tips and tricks to help you succeed:

-

Systems Engineering:

- Use a model-based systems engineering approach to capture system requirements and design

- Engage with stakeholders early and often to gather their input and feedback

- Conduct thorough risk analysis and mitigation planning

-

Industrial Engineering:

- Use data analysis tools to identify bottlenecks and opportunities for improvement

- Implement lean manufacturing techniques to reduce waste and improve efficiency

- Engage with employees to get their insights and suggestions for improvement

Conclusion

Systems engineering and industrial engineering are two distinct yet complementary disciplines that play vital roles in the design, optimization, and management of complex systems. By understanding the differences between these two fields, professionals can leverage their unique strengths to develop innovative solutions that meet the needs of customers and stakeholders. Collaboration between systems engineers and industrial engineers is essential to the success of many complex systems projects, ensuring that these systems are both robust and efficient.