In today’s competitive business landscape, organizations face relentless pressure to optimize productivity, streamline processes, and stay ahead of the curve. Specialization in production presents itself as a cornerstone strategy for achieving these goals. By dedicating resources and expertise to specific areas of production, businesses unlock a wealth of benefits that contribute to sustained growth and profitability.

Increased Efficiency and Productivity

The primary advantage of specialization in production lies in its ability to enhance efficiency and productivity. Through focused training and targeted investments, businesses can develop a highly skilled workforce that possesses in-depth knowledge of specific production processes and techniques. This expertise enables employees to execute tasks with greater precision, speed, and accuracy, leading to significant improvements in operational performance.

According to the International Labor Organization (ILO), specialization in production has been linked to productivity gains of up to 20%. By eliminating the need for workers to switch between different tasks, businesses can minimize wasted time and effort, resulting in a more efficient and streamlined production process.

Enhanced Product Quality and Consistency

Specialization in production also contributes to improved product quality and consistency. By focusing on a narrower range of products, businesses can allocate resources and expertise to optimizing each step of the production process. This increased attention to detail and rigorous quality control measures ensure that products meet the highest standards of excellence.

The American Society for Quality (ASQ) estimates that specialization in production can reduce product defects by as much as 50%. By identifying and eliminating potential sources of error, businesses can enhance customer satisfaction, build brand reputation, and minimize the risk of costly recalls.

Innovation and Value Creation

Specialization in production serves as a catalyst for innovation and value creation. By fostering a deep understanding of specific production processes, businesses develop the ability to identify and implement innovative solutions that improve efficiency, reduce costs, and enhance product performance.

For example, Toyota’s renowned production system, known as “lean manufacturing,” resulted from a specialized focus on reducing waste and optimizing production processes. This approach has led to significant cost reductions, improved product quality, and increased customer satisfaction for the company.

Economies of Scale and Specialization

Specialization in production also enables businesses to achieve economies of scale. By concentrating on a specific area of production, businesses can leverage their purchasing power to negotiate favorable deals with suppliers, reduce unit costs, and increase profit margins.

Additionally, specialization allows businesses to invest in specialized equipment and technologies that would not be feasible for a wider range of production activities. This investment can further enhance efficiency, productivity, and product quality.

Impact on Labor and Employment

While specialization in production offers numerous benefits, it also has potential implications for labor and employment. The increased automation and technological advancements associated with specialized production processes can lead to job displacement in some sectors.

However, the overall impact on employment is often nuanced and depends on the specific industry and region. Specialization can also create new opportunities for skilled workers in specialized fields, requiring higher levels of training and expertise.

Considerations for Implementation

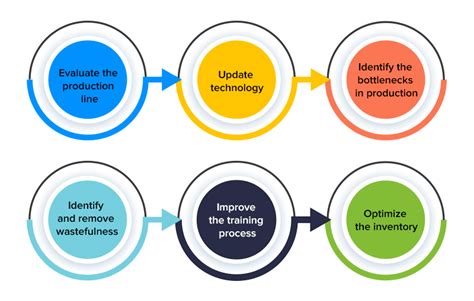

Organizations considering specialization in production should carefully evaluate their objectives, resources, and market dynamics before implementing this strategy. Key factors to consider include:

- Adequate Market Demand: Ensure that there is sufficient demand for specialized products or services to justify the investment in specialization.

- Availability of Skilled Labor: Confirm the availability of a skilled workforce with the required expertise or the ability to invest in training and development programs.

- Technological Infrastructure: Assess whether the necessary equipment and technologies are available to support specialized production processes.

- Competitive Landscape: Analyze the competitive environment to identify potential threats and opportunities associated with specialization.

Conclusion

Specialization in production is a strategic imperative for businesses seeking to enhance efficiency, productivity, and innovation. Through focused training, targeted investments, and a relentless pursuit of quality, organizations can develop a highly specialized workforce that drives exceptional results. While considerations for labor and employment must be carefully weighed, specialization in production holds immense potential to unlock competitive advantages, drive growth, and create lasting value for businesses and their customers alike.