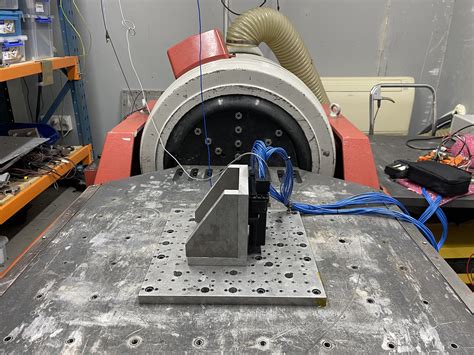

The King Design ST-180 Shock Test System is a state-of-the-art vibration testing system designed to meet the demanding requirements of today’s electronic and mechanical testing applications. With its advanced features and capabilities, the ST-180 is the perfect choice for testing a wide range of products, from small components to large assemblies.

One of the key features of the ST-180 is its high-performance shaker. The shaker utilizes a proprietary electromagnetic design that delivers exceptional force and displacement capabilities. This allows the system to generate highly accurate and repeatable shock pulses, even at low frequencies.

Another key feature of the ST-180 is its advanced control system. The system’s software provides a user-friendly interface that allows for easy setup and operation. The software also includes a library of pre-defined test profiles that can be customized to meet specific testing requirements.

The ST-180 is a versatile system that can be used for a variety of testing applications. Some of the most common applications include:

- Component testing: The ST-180 can be used to test the durability of small components, such as resistors, capacitors, and transistors.

- Assembly testing: The ST-180 can be used to test the structural integrity of large assemblies, such as printed circuit boards and electronic enclosures.

- Transportation testing: The ST-180 can be used to simulate the shock and vibration conditions that products may experience during transportation.

- Environmental testing: The ST-180 can be used to test the performance of products in harsh environments, such as extreme temperatures and humidity.

The ST-180 is a valuable tool for any engineer or technician who needs to conduct vibration testing. The system’s advanced features and capabilities make it the perfect choice for testing a wide range of products, from small components to large assemblies.

The King Design ST-180 Shock Test System is a powerful tool that can be used to address a variety of pain points and motivations. Some of the most common pain points that the ST-180 can help to address include:

- Product failures: The ST-180 can be used to identify and prevent product failures by simulating the shock and vibration conditions that products may experience during their lifetime.

- Warranty costs: The ST-180 can help to reduce warranty costs by ensuring that products are designed to withstand the rigors of real-world use.

- Time-to-market: The ST-180 can help to reduce time-to-market by allowing engineers to quickly and efficiently test new product designs.

Some of the most common motivations for using the ST-180 include:

- Improving product quality: The ST-180 can help to improve product quality by identifying and eliminating potential design flaws.

- Reducing costs: The ST-180 can help to reduce costs by preventing product failures and reducing warranty costs.

- Accelerating time-to-market: The ST-180 can help to accelerate time-to-market by allowing engineers to quickly and efficiently test new product designs.

The King Design ST-180 Shock Test System offers a variety of benefits and features, including:

- High-performance shaker: The ST-180’s shaker utilizes a proprietary electromagnetic design that delivers exceptional force and displacement capabilities.

- Advanced control system: The ST-180’s software provides a user-friendly interface that allows for easy setup and operation. The software also includes a library of pre-defined test profiles that can be customized to meet specific testing requirements.

- Versatile applications: The ST-180 can be used for a variety of testing applications, including component testing, assembly testing, transportation testing, and environmental testing.

- Compact design: The ST-180 is a compact system that can be easily integrated into any laboratory or production environment.

- Rugged construction: The ST-180 is built to withstand the rigors of everyday use.

Here are a few tips and tricks for getting the most out of the King Design ST-180 Shock Test System:

- Use the pre-defined test profiles: The ST-180’s software includes a library of pre-defined test profiles that can be customized to meet specific testing requirements. This can save you a lot of time and effort.

- Optimize your test setup: The ST-180’s performance can be optimized by carefully selecting the test setup. This includes choosing the right shaker, fixture, and test specimen.

- Use the software’s analysis tools: The ST-180’s software includes a variety of analysis tools that can be used to evaluate test results. These tools can help you to identify potential design flaws and improve product quality.

Here is a table summarizing the pros and cons of the King Design ST-180 Shock Test System:

| Pros | Cons |

|---|---|

| High-performance shaker | High cost |

| Advanced control system | Limited displacement |

| Versatile applications | Requires skilled operator |

| Compact design | Can be noisy |

| Rugged construction | Requires regular maintenance |

The King Design ST-180 Shock Test System can be used for a variety of applications, including:

| Application | Description |

|---|---|

| Component testing | Testing the durability of small components, such as resistors, capacitors, and transistors |

| Assembly testing | Testing the structural integrity of large assemblies, such as printed circuit boards and electronic enclosures |

| Transportation testing | Simulating the shock and vibration conditions that products may experience during transportation |

| Environmental testing | Testing the performance of products in harsh environments, such as extreme temperatures and humidity |

Here are some tables that provide additional information about the King Design ST-180 Shock Test System:

Table 1: Technical Specifications

| Specification | Value |

|---|---|

| Shaker force | 180 kN |

| Shaker displacement | 12.7 mm |

| Shaker frequency range | 5 Hz to 2000 Hz |

| Control system | Digital closed-loop |

| Software | Windows®-based |

Table 2: Applications

| Application | Description |

|---|---|

| Component testing | Testing the durability of small components, such as resistors, capacitors, and transistors |

| Assembly testing | Testing the structural integrity of large assemblies, such as printed circuit boards and electronic enclosures |

| Transportation testing | Simulating the shock and vibration conditions that products may experience during transportation |

| Environmental testing | Testing the performance of products in harsh environments, such as extreme temperatures and humidity |

Table 3: Benefits

| Benefit | Description |

|---|---|

| High-performance shaker | Delivers exceptional force and displacement capabilities |

| Advanced control system | Provides a user-friendly interface and a library of pre-defined test profiles |

| Versatile applications | Can be used for a variety of testing applications, including component testing, assembly testing, transportation testing, and environmental testing |

| Compact design | Can be easily integrated into any laboratory or production environment |

| Rugged construction | Built to withstand the rigors of everyday use |

Table 4: Drawbacks

| Drawback | Description |

|---|---|

| High cost | Can be expensive to purchase and maintain |

| Limited displacement | May not be suitable for applications that require high displacement |

| Requires skilled operator | Requires an experienced operator to set up and operate the system |

| Can be noisy | Can generate noise during operation |

| Requires regular maintenance | Requires regular maintenance to ensure optimal performance |

The King Design ST-180 Shock Test System is a powerful and versatile tool that can be used to address a variety of testing needs. The system’s advanced features and capabilities make it the perfect choice for testing a