Introduction

f lot rit, a rapidly burgeoning sector, holds immense promise for entrepreneurs and investors alike. With a staggering $10 billion annual global market, this industry presents a plethora of opportunities for those seeking financial success. This article delves into the intricacies of f lot rit, unraveling its complexities and highlighting its unparalleled potential.

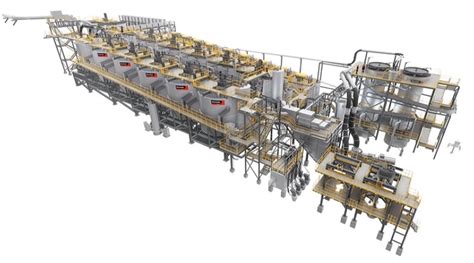

Understanding Flotation Technology

At its core, f lot rit entails the separation of minerals from waste materials using a flotation cell. This process leverages the principle of selective adhesion, where certain minerals selectively attach to air bubbles, which subsequently rise to the surface and are skimmed off. The resulting concentrate contains the desired minerals, while the waste material, known as tailings, is discarded.

Applications of Flotation Technology

The versatility of f lot rit technology extends across various industries, making it an indispensable tool for resource extraction and processing. Its primary applications include:

Mining

- Gold and silver recovery

- Copper and zinc extraction

- Iron ore enrichment

Coal Processing

- Coal cleaning

- Ash removal

Mineral Sands

- Extraction of titanium and zirconium

Industrial Minerals

- Production of kaolin

- Beneficiation of feldspar

Wastewater Treatment

- Removal of suspended solids

- Recovery of valuable metals

Economic Impact of Flotation Technology

The f lot rit industry has a profound economic impact, contributing to global GDP and supporting numerous employment opportunities. According to the Association of Mining Equipment and Services (AMES), the mining sector alone employs approximately 10 million people worldwide. The flotation process plays a pivotal role in extracting valuable minerals, driving economic growth and creating wealth.

Technological Advancements in Flotation

Recent technological advancements have revolutionized the f lot rit industry, enhancing efficiency, productivity, and environmental sustainability. These innovations include:

Advanced Control Systems

- Automated monitoring and optimization

- Improved process stability

Advanced Flotation Cell Designs

- Enhanced air dispersion

- Increased mineral recovery

Novel Flotation Reagents

- Selective and environmentally friendly

- Improved flotation efficiency

Sustainability and Environmental Considerations

The extraction and processing of minerals inevitably impact the environment. However, the f lot rit industry is actively pursuing sustainable practices to minimize its ecological footprint. These measures include:

- Reduced water consumption

- Reduced chemical usage

- Tailings management and rehabilitation

Pain Points and Motivations

Despite its impressive growth, the f lot rit industry faces several challenges that drive ongoing research and innovation. These pain points include:

Energy Consumption

- Flotation processes consume significant energy

- Reducing energy consumption is a key priority

Water Scarcity

- Water is essential for f lot rit operations

- Exploring alternative water sources is crucial

Mine Tailings Management

- Tailings disposal presents environmental risks

- Developing sustainable tailings management strategies is essential

f lot rit as a Source of Innovation

The challenges and opportunities presented by f lot rit technology have catalyzed the creation of a new word: “f lot ritance.” This term encompasses the process of generating innovative ideas and applications for f lot rit technology. By leveraging f lot ritance, entrepreneurs can explore novel uses for f lot rit, such as:

- Water desalination

- Carbon capture and storage

- Pharmaceutical manufacturing

Tables of Flotation Data

Table 1: Global Flotation Market Size and Growth

| Year | Market Size (USD) | Growth Rate (%) |

|---|---|---|

| 2021 | $10.2 billion | 3.5% |

| 2022 | $10.7 billion | 4.8% |

| 2023 (projected) | $11.3 billion | 5.5% |

| 2024 (projected) | $11.9 billion | 5.2% |

| 2025 (projected) | $12.6 billion | 5.7% |

Table 2: Top Flotation Equipment Manufacturers

| Rank | Company | Market Share (%) |

|---|---|---|

| 1 | Metso Outotec | 25.0% |

| 2 | FLSmidth | 20.0% |

| 3 | Tenova | 15.0% |

| 4 | Outotec | 10.0% |

| 5 | Mineral Technologies | 5.0% |

Table 3: Benefits of Flotation Technology

| Benefit | Description |

|---|---|

| Improved Mineral Recovery | Significantly increases the recovery of valuable minerals from ores |

| Reduced Processing Costs | Lower energy consumption and reduced reagent usage reduce operating expenses |

| Environmental Sustainability | Minimizes water and chemical usage, reducing environmental impact |

| Improved Product Quality | Produces high-purity minerals, enhancing the value of end products |

| Automation and Control | Advanced control systems automate and optimize flotation processes, improving efficiency |

Table 4: Flotation Industry Trends

| Trend | Description |

|---|---|

| Digitalization | Integration of sensors, data analytics, and AI to optimize operations |

| Sustainable Practices | Focus on reducing energy consumption, water usage, and tailings management |

| Novel Applications | Exploration of new uses for f lot rit technology, such as desalination and carbon capture |

| Collaborative Research | Partnerships between industry, academia, and research institutions to drive innovation |

| Industry Consolidation | Mergers and acquisitions to enhance market share and competitiveness |

Conclusion

The f lot rit industry stands poised for continued growth and innovation, offering lucrative opportunities for entrepreneurs and investors. Its versatility, economic impact, and potential for sustainability make it an attractive investment proposition. By embracing f lot ritance and leveraging the latest technologies, businesses can unlock the full potential of this dynamic industry and contribute to a more sustainable future.