Introduction

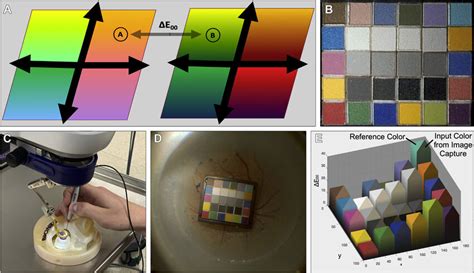

Color is a fundamental aspect of our world and plays a crucial role in various industries, including manufacturing, textiles, painting, and photography. However, accurately measuring and communicating color differences can be challenging. This is where Delta E, a metric that quantifies the perceived color difference between two samples, becomes essential.

Understanding Delta E

Delta E is calculated using mathematical formulas that take into account three main components of color:

- Luminance (L*)

- Red-green coordinate (a*)

- Yellow-blue coordinate (b*)

The formula for Delta E, also known as the Euclidean distance, is as follows:

ΔE = √((L*2 - L*1)² + (a*2 - a*1)² + (b*2 - b*1)²)

where:

- ΔE represents the color difference

- L1, a1, b*1 are the coordinates of the first sample

- L2, a2, b*2 are the coordinates of the second sample

The Delta E value provides a numerical measure of the color difference between the two samples, with a higher value indicating a greater difference.

Applications of Delta E

Delta E has numerous applications across various industries:

Manufacturing:

* To ensure quality control and consistency in product colors

* To compare colors of different materials and finishes

Textiles:

* To evaluate color accuracy in fabric dyeing and printing

* To predict the color fastness of textiles under different conditions

Painting:

* To determine the best color combination and harmonization

* To match paint colors to existing surfaces or objects

Photography:

* To edit and correct color differences in digital images

* To ensure consistent color reproduction across different platforms

Common Mistakes to Avoid

When using Delta E, it is crucial to avoid the following common mistakes:

- Assuming that a low Delta E value indicates no visible color difference: The human eye is more sensitive to certain color differences than others. A Delta E value below 2 may not be visually perceptible, but it may be noticeable under certain lighting conditions.

- Ignoring the context of the application: The acceptable Delta E value varies depending on the specific industry and application. For example, a Delta E of 2 may be acceptable in textile manufacturing, but it may be unacceptable in color-critical applications such as photography.

- Using Delta E as the sole measure of color difference: Other factors, such as metamerism (color differences under different light sources) and the influence of surface texture, should also be considered.

Why Delta E Matters

Accurately quantifying color differences is essential for several reasons:

- Quality Control: Ensure that products meet specified color standards.

- Consistency: Maintain consistent color across different batches or products.

- Customer Satisfaction: Avoid color-related complaints or dissatisfaction.

- Brand Identity: Preserve the brand’s visual identity by maintaining consistent colors in logos and marketing materials.

- Cost Savings: Reduce production errors and rework costs due to incorrect colors.

Benefits of Using Delta E

- Objective Measure: Provides a numerical value that eliminates subjective judgments.

- Universal Standard: Recognized and used globally, facilitating communication between industries and countries.

- Accuracy: Calculates color differences based on mathematical formulas, ensuring precision.

- Simplicity: Easy to understand and implement in various applications.

- Versatility: Applicable to different industries and materials, from textiles to paints and digital images.

FAQs

-

What is an acceptable Delta E value?

It depends on the application. Generally, a Delta E below 2 is considered barely noticeable, while values above 5 are easily visible. -

Can I use Delta E to measure all types of color differences?

No, Delta E is specifically designed for measuring perceived color differences. It does not account for metamerism or surface texture effects. -

How can I improve the accuracy of Delta E calculations?

Use appropriate lighting conditions, calibrate measurement equipment, and consider the viewing angle and surface texture of the samples. -

Are there other metrics for measuring color differences?

Yes, other metrics include CIELAB Delta E (ΔEab), CIEDE2000 (ΔE00), and DIN99 (ΔD). -

How is Delta E used in quality control?

Manufacturers set acceptable Delta E limits to ensure that products meet color specifications. Inspections and audits are performed to verify compliance. -

What are some creative applications of Delta E?

Delta E can be used to develop color-matching algorithms, create virtual color palettes, and analyze the effects of light on color perception.