Cylindrical spheroids, also known as elliptical cylinders, are a class of three-dimensional shapes characterized by their elongated, cylindrical-like form and curved cross-sections. Despite their often-overlooked status in the realm of structural design, these versatile shapes hold immense promise for unlocking new frontiers of architectural ingenuity and engineering prowess.

Structural Advantages of Cylindrical Spheroids

-

Enhanced Strength and Stability: Cylindrical spheroids possess exceptional structural integrity due to their smooth, continuous curvature. This curvature evenly distributes stresses and strains throughout the structure, making them highly resistant to bending, buckling, and collapse.

-

Optimized Load-Bearing Capacity: The elliptical cross-section of cylindrical spheroids allows for efficient load distribution, with the maximum stress concentrations occurring at the cylinder’s ends. This enables them to carry significant loads without excessive deflection or material degradation.

-

Aerodynamic Efficiency: The streamlined shape of cylindrical spheroids reduces aerodynamic drag, making them ideal for applications where wind resistance is a key design consideration. Their smooth contours minimize airflow disruption, leading to improved energy efficiency and performance.

Applications in Various Industries

-

Architecture: Cylindrical spheroids have garnered attention in architectural circles for their unique aesthetic appeal and structural capabilities. They have been incorporated into iconic structures such as the Stadium of Light in Sunderland, England, and the Shanghai Grand Theater in China, showcasing their versatility in creating both elegant and functional spaces.

-

Aerospace Engineering: Aerospace engineers leverage the aerodynamic efficiency of cylindrical spheroids in the design of aircraft fuselages, wings, and engine pods. Their ability to withstand high-stress environments and optimize airflow makes them a valuable asset in the pursuit of aerodynamic performance and fuel efficiency.

-

Civil Engineering: Cylindrical spheroids find applications in the construction of bridges, tunnels, and other large-scale infrastructure projects. Their structural strength and resistance to seismic loads ensure the integrity and durability of these critical structures.

-

Automotive Design: Automotive manufacturers use cylindrical spheroids in the design of car frames, bumpers, and exterior panels. Their ability to absorb and distribute impact forces enhances safety and extends the life of vehicles.

Material Considerations and Manufacturing Techniques

The choice of materials for cylindrical spheroid structures depends on the specific application requirements. Common materials include:

- Steel: Provides high strength, durability, and resistance to corrosion.

- Concrete: Offers compressive strength, fire resistance, and cost-effectiveness.

- Composite Materials: Combine the properties of multiple materials, such as high strength, lightweight, and corrosion resistance.

Various manufacturing techniques are employed to create cylindrical spheroids, including:

- Rolling and Shaping: Cylindrical sheet metal is rolled and bent to the desired shape.

- Casting: Molten metal is poured into a mold and allowed to solidify.

- Composite Lay-up: Layers of composite materials are laid up and bonded together.

- 3D Printing: Advanced 3D printing technologies enable the creation of complex, customized cylindrical spheroid structures.

Applications of Cylindrical Spheroids: A Brainstorming Exercise

To unleash the full potential of cylindrical spheroids, it is essential to think beyond traditional applications. Here are some creative ideas for novel uses:

-

Wind Turbine Blades: The aerodynamic efficiency of cylindrical spheroids could enhance the performance and efficiency of wind turbines.

-

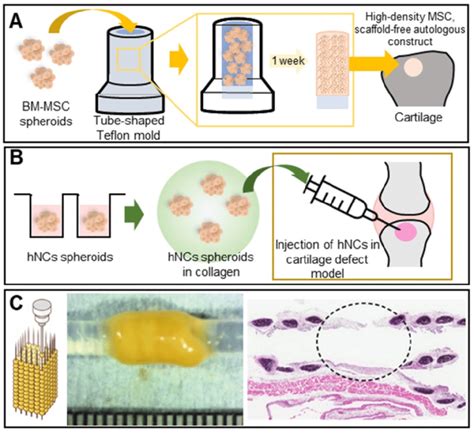

Biomedical Implants: The smooth curvature and structural integrity of cylindrical spheroids make them suitable for use in orthopedic and dental implants, providing long-lasting support and reducing implant failure rates.

-

Submarine Hulls: Cylindrical spheroids could revolutionize submarine design by providing superior underwater maneuvering capabilities and stealth characteristics.

-

Satellite Antennas: The smooth, elliptical shape of cylindrical spheroids could minimize signal distortion and improve the performance of satellite communications systems.

-

Art and Sculptures: The unique aesthetic appeal of cylindrical spheroids presents opportunities for artists and sculptors to create captivating works of art that push the boundaries of design and creativity.

Research and Development

Ongoing research and development efforts are further expanding the applications of cylindrical spheroids. Key areas of focus include:

-

Material Science: Developing new materials with improved strength, durability, and weight reduction capabilities.

-

Design Optimization: Using computational modeling and simulation techniques to optimize the structural performance and efficiency of cylindrical spheroids.

-

Manufacturing Technologies: Advancements in manufacturing techniques to produce complex, precision-engineered cylindrical spheroids with high accuracy and cost-effectiveness.

Conclusion

Cylindrical spheroids, once overlooked in the realm of structural design, have emerged as a transformative force in engineering and architecture. Their exceptional structural properties, aerodynamic efficiency, and versatility open up a myriad of possibilities for innovation and progress. By continuing to explore the potential of these intriguing shapes, we can unlock new horizons in structural design and shape the future of our built environment.