In the realm of theater and performing arts, the ability to manipulate the stage is paramount. It allows for dynamic scene transitions, captivating audience engagement, and an overall immersive experience. Among the various mechanisms employed for stage movement, the hydraulic system stands out as a powerful and versatile force.

The Working Mechanism of a Hydraulic System

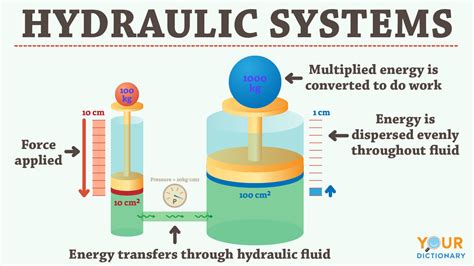

A hydraulic system is an assembly of interconnected components that utilize pressurized fluid to transmit power and motion. In the context of stage machinery, the hydraulic system consists of:

- Reservoir: A tank that stores the hydraulic fluid.

- Pump: A device that creates pressure by pumping fluid through the system.

- Valves: Control devices that regulate the flow of fluid.

- Cylinders: Actuators that convert hydraulic pressure into linear or rotary motion.

- Hydraulic fluid: A specialized fluid that transmits power without losing energy due to friction.

The Role of Hydraulic Fluid

Hydraulic fluid is the lifeblood of the system, acting as the medium for power transmission. Its incompressible nature ensures that the pressure applied to the fluid is transmitted throughout the system with minimal loss. The viscosity of the fluid, a measure of its resistance to flow, affects the system’s responsiveness and efficiency.

Cylinders: The Movers and Shakers

Cylinders are the workhorses of the hydraulic system, converting hydraulic pressure into mechanical motion. They exist in two primary types:

- Linear cylinders: Extend or retract along a straight line, pushing or pulling stage elements.

- Rotary cylinders: Convert hydraulic pressure into rotation, driving turntables or other rotating stage components.

Advantages of Hydraulic Systems for Stage Movement

- Power and Precision: Hydraulic systems offer immense power, capable of lifting heavy stage elements and providing precise control over their movement.

- Versatility: Hydraulic cylinders can be easily configured to accommodate different stage configurations and movement requirements.

- Smoothness and Control: The incompressible nature of hydraulic fluid ensures smooth and controlled transitions, minimizing vibrations and noise.

- Reliability: Hydraulic systems are renowned for their durability and reliability, withstanding demanding performance conditions.

Common Mistakes to Avoid in Hydraulic System Design

- Underestimating Pressure Requirements: Accurately assessing the force required to move stage elements is crucial to avoid system failure.

- Ignoring Fluid Viscosity: Choosing the optimal hydraulic fluid viscosity is essential for efficient system operation and responsiveness.

- Neglecting Maintenance: Regular system maintenance, including fluid changes and component inspections, is paramount for longevity and reliability.

- Insufficient Filtration: Contaminants in the hydraulic fluid can lead to premature component wear and system failure. Proper filtration is imperative.

Step-by-Step Approach to Hydraulic System Installation

- Determine System Requirements: Assess the stage movement needs, including load capacity and precision requirements.

- Design the System: Select components, layout the piping, and calculate pressure and flow rates.

- Install the System: Follow manufacturer guidelines for component installation and system assembly.

- Test and Commission the System: Conduct thorough testing to verify system functionality and adjust settings as necessary.

- Maintain and Service the System: Implement a regular maintenance program to ensure optimal performance and longevity.

Innovative Applications of Hydraulics in Stage Machinery

Beyond traditional stage movement, hydraulic systems have inspired creative applications that enhance the audience experience:

- Automated Scenery Changes: Hydraulics enable the seamless and efficient movement of scenery elements, creating dynamic and visually stunning transitions.

- Dynamic Orchestra Platforms: Hydraulics allow orchestra platforms to rise from below stage level, providing a dramatic and immersive musical experience.

- Flying Trapeze Systems: Hydraulics power the lifting mechanisms for trapeze artists, enabling gravity-defying aerial performances.

Frequently Asked Questions (FAQs)

- What are the safety considerations for hydraulic systems? Hydraulic systems operate under high pressure; proper training, protective gear, and maintenance procedures are mandatory.

- How do I choose the right hydraulic fluid? Consult with equipment manufacturers and fluid specialists to determine the optimal viscosity, temperature stability, and compatibility with system components.

- How often should I service my hydraulic system? Maintenance intervals vary depending on system usage and environmental conditions; consult manufacturer recommendations for specific guidelines.

- What are the potential troubleshooting issues for hydraulic systems? Common issues include leaks, pressure drops, and component failures; thorough maintenance and regular inspections can minimize these occurrences.

- Can hydraulic systems be retrofitted to existing stages? Yes, retrofitting is possible, but it requires careful planning and compatibility assessment with the existing infrastructure.

- What are the environmental considerations for hydraulic systems? Choose environmentally friendly hydraulic fluids and implement proper disposal procedures to minimize environmental impact.

Conclusion

Hydraulic systems play a pivotal role in stage movement, providing power, precision, and versatility. By understanding the system components, their interactions, and best practices, engineers and technicians can design and maintain hydraulic systems that enable the creation of captivating and memorable stage productions. As technology continues to advance, hydraulics will continue to inspire innovative applications, pushing the boundaries of stage design and enhancing the audience experience.