Introduction

CCD (Charge-Coupled Device) testing centers play a pivotal role in ensuring the accuracy and reliability of digital medical images. These facilities utilize advanced equipment and expertise to evaluate the performance of CCDs, which are essential components of medical imaging devices such as CT and MRI scanners. By conducting thorough testing, CCD testing centers help healthcare providers make informed decisions about the quality and functionality of their imaging systems.

Benefits of CCD Testing

CCD testing offers numerous advantages for healthcare organizations and professionals:

- Improved Image Quality: Accurate CCD testing ensures that medical images are free from distortions, artifacts, and noise, leading to enhanced diagnostic accuracy.

- Optimized Equipment Performance: Regular testing helps identify and address performance issues with CCDs, optimizing scanner utilization and extending their lifespan.

- Reduced Downtime: By proactively testing CCDs, healthcare providers can minimize the risk of equipment downtime, ensuring continuity of patient care and reducing operational costs.

- Compliance with Regulations: CCD testing complies with regulatory standards set by accrediting bodies such as the American College of Radiology (ACR) and the Joint Commission (TJC).

- Enhanced Patient Safety: Reliable CCDs contribute to accurate diagnoses and timely treatment, improving patient outcomes and reducing the risk of misdiagnoses.

Types of CCD Testing

CCD testing centers perform various types of evaluations to assess the performance of these devices:

Performance Testing

- Dark Current Measurement: Measures the amount of electrical current generated by a CCD in the absence of light, indicating the presence of noise.

- Signal-to-Noise Ratio (SNR): Determines the ratio of the signal generated by the CCD to the background noise, indicating image quality.

- Detective Quantum Efficiency (DQE): Assesses the ability of the CCD to detect and convert X-ray photons into electrical signals, indicating image sensitivity.

Geometric Testing

- Geometric Distortion: Measures the deviation from ideal geometric properties, such as linearity and symmetry, affecting image accuracy.

- Pixel Geometry: Evaluates the size, shape, and alignment of individual CCD pixels, ensuring proper image resolution and clarity.

Stability Testing

- Temperature Stability: Assesses the consistency of CCD performance over a range of temperatures, minimizing image artifacts.

- Long-Term Stability: Monitors the performance of CCDs over an extended period, indicating reliability and durability.

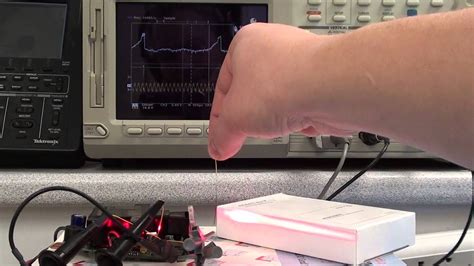

CCD Testing Process

The CCD testing process typically involves the following steps:

- Equipment Verification: The testing center verifies the calibration and functionality of its equipment.

- CCD Installation: The CCD is installed in the testing device, such as a collimator or calibration phantom.

- Testing Procedures: The CCD undergoes a series of tests according to established protocols.

- Data Analysis: The test results are analyzed and interpreted by experienced technicians.

- Reporting: A comprehensive report detailing the test results and recommendations is generated.

Choosing a CCD Testing Center

When selecting a CCD testing center, healthcare providers should consider the following factors:

- Accreditation: Look for centers accredited by reputable organizations like the ACR or TJC.

- Expertise: Choose centers with experienced and knowledgeable staff who specialize in CCD testing.

- Testing Capabilities: Ensure the center offers a comprehensive range of testing services to meet your specific requirements.

- Turnaround Time: Consider the center’s ability to provide timely test results to minimize downtime.

- Cost: Compare the fees charged by different centers and choose one that aligns with your budget.

Applications of CCD Testing

Beyond traditional medical imaging, CCD testing has found innovative applications in various fields:

- Photon Counting Spectroscopy: CCDs are used to detect and count individual photons in ultra-low-light applications.

- Machine Vision: CCDs are employed in industrial settings for automated visual inspection and quality control.

- Astronomical Imaging: CCDs are used in telescopes and other astronomical instruments to capture high-resolution images of celestial bodies.

- LIDAR Systems: CCDs are incorporated into LIDAR systems to generate high-density, 3D point clouds for mapping and autonomous navigation.

Tables

Table 1: CCD Testing Parameters and Typical Values

| Parameter | Typical Value |

|---|---|

| Dark Current | < 100 e-/s |

| Signal-to-Noise Ratio | > 100:1 |

| Detective Quantum Efficiency | > 70% |

Table 2: CCD Testing Equipment

| Equipment | Function |

|---|---|

| Collimator | Directs X-rays to the CCD |

| Calibration Phantom | Provides a known image pattern for testing |

| Signal Generator | Generates electrical signals for testing |

| Data Acquisition System | Records CCD output data |

Table 3: Benefits and Challenges of CCD Testing

| Benefits | Challenges |

|---|---|

| Improved image quality | Costly equipment |

| Optimized equipment performance | Time-consuming process |

| Reduced downtime | Limited availability of qualified technicians |

| Compliance with regulations | Need for ongoing training |

| Enhanced patient safety | Interpretation of test results requires expertise |

Table 4: FAQs about CCD Testing

| Question | Answer |

|---|---|

| What is the purpose of CCD testing? | To evaluate the performance and reliability of CCDs |

| How often should CCDs be tested? | According to manufacturer recommendations or regulatory requirements |

| What are the signs that a CCD may need testing? | Image artifacts, noise, or performance issues |

| Who should perform CCD testing? | Experienced technicians at accredited testing centers |

| How much does CCD testing cost? | Varies depending on the center and type of testing |