3D printing, also known as additive manufacturing, has evolved from a prototyping tool to a versatile production technology. This transformative technology has revolutionized industries, from aerospace to healthcare, enabling the creation of complex and customized products with unprecedented efficiency.

3D Printing Technology: An Overview

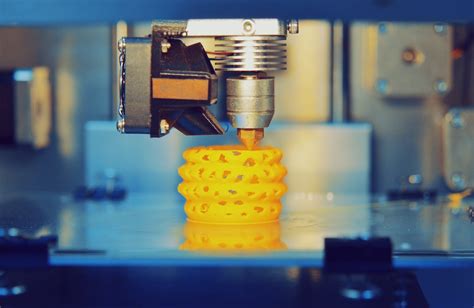

3D printing involves depositing layers of material to create three-dimensional objects. The process begins with a digital model, which is sliced into thin cross-sections. A specialized printer then deposits the material, layer by layer, building the object from the ground up.

Materials and Applications of 3D Printing

3D printing can utilize a vast range of materials, including plastics, metals, ceramics, and even biological materials. This versatility allows for the creation of products with diverse properties, such as strength, flexibility, and heat resistance.

-

Automotive Industry: 3D printing enables rapid prototyping of automotive parts, reducing development time and costs. It also allows for the production of lightweight and customized components, improving vehicle performance and aesthetics.

-

Aerospace Industry: 3D printing has revolutionized aerospace manufacturing, enabling the creation of lighter and more durable aircraft components. It also allows for the production of complex shapes that were previously impossible to manufacture using traditional methods.

-

Medical Industry: 3D printing has transformative applications in healthcare. It enables the creation of patient-specific medical devices, such as prosthetics and implants, that are tailored to individual needs. It also allows for the rapid prototyping of medical devices and surgical planning, improving patient outcomes.

Benefits of 3D Printing

-

Reduced Costs: 3D printing eliminates the need for expensive tooling and molds, reducing manufacturing costs. It also allows for the production of small batches or customized products without significant cost penalties.

-

Rapid Prototyping: 3D printing enables rapid prototyping, allowing designers to test and refine new products quickly and efficiently. This reduces development time and minimizes the risk of costly errors.

-

Design Flexibility: 3D printing provides unparalleled design flexibility. It allows designers to create complex and organic shapes that were previously impossible to manufacture. This opens up new possibilities for product design and innovation.

-

Sustainability: 3D printing can contribute to sustainability by reducing waste and energy consumption. It allows for the production of products on-demand, reducing the need for excess inventory and transportation.

Challenges and Future of 3D Printing

-

Material Limitations: While 3D printing materials have improved significantly, some limitations still exist. Certain materials, such as high-performance composites, can be challenging to print consistently.

-

Speed and Efficiency: 3D printing can be slower than traditional manufacturing methods for larger production runs. However, advancements in technology and the development of new materials are continuously improving print speed and efficiency.

The future of 3D printing holds immense promise. Researchers are developing new printing technologies, such as multi-material and multi-process printing, that will further enhance the capabilities of this versatile technology. Moreover, the integration of artificial intelligence and machine learning will automate many aspects of the 3D printing process, reducing costs and improving efficiency.

Step-by-Step Approach to Implement 3D Printing

-

Identify a Suitable Application: Assess your business needs and identify areas where 3D printing can offer benefits.

-

Acquire a 3D Printer: Determine the appropriate 3D printer based on your materials, build volume, and accuracy requirements.

-

Create Digital Models: Design or acquire 3D models of the objects you want to print. Ensure the models are optimized for 3D printing.

-

Optimize Print Settings: Calibrate the printer and adjust print settings to achieve optimal surface quality, strength, and accuracy.

-

Print and Post-Process: Print the objects and perform any necessary post-processing, such as curing, sanding, or finishing, to enhance the final product.

Why 3D Printing Matters

3D printing technology is revolutionizing industries by:

-

Empowering Innovation: 3D printing unlocks new possibilities for product design and enables the creation of innovative and complex products that were previously impossible to manufacture.

-

Improving Efficiency: 3D printing reduces development time, eliminates tooling costs, and enables rapid prototyping, resulting in increased efficiency and reduced costs.

-

Driving Customization: 3D printing allows for the production of personalized and customized products, meeting the unique needs of individual customers.

-

Expanding Access: 3D printing makes manufacturing more accessible, enabling small businesses and entrepreneurs to compete in an increasingly competitive market.

Conclusion

3D printing is a transformative technology that has the potential to disrupt and reinvent entire industries. By embracing its versatility and benefits, businesses can create innovative products, improve efficiency, and revolutionize their operations. As the technology continues to evolve, we can expect even more exciting applications and advancements in the future.